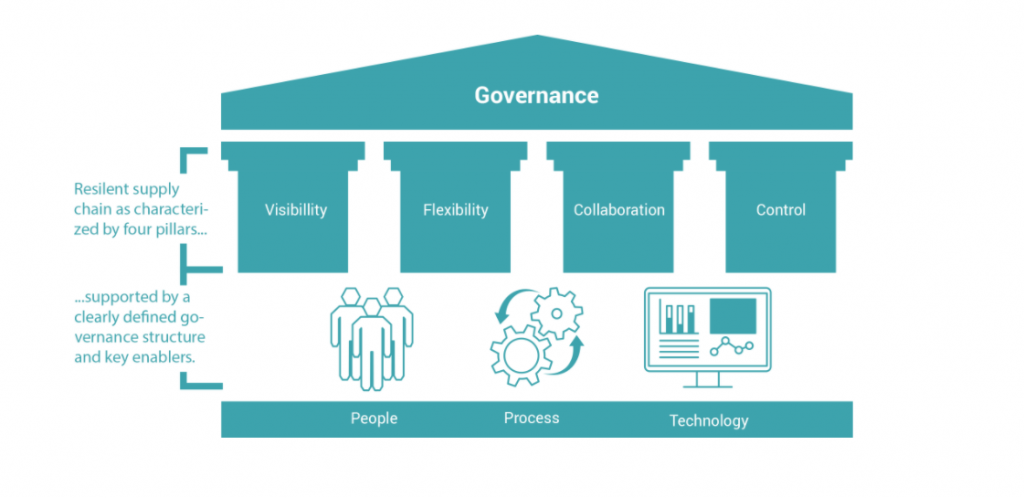

Provide end-to-end visibility into supply chain performance

Provide flexibility to thrive under supply volatility and market uncertainty

Effectively collaborate and coordinate with suppliers around the globe

Control costs through process optimization throughout the supply chain

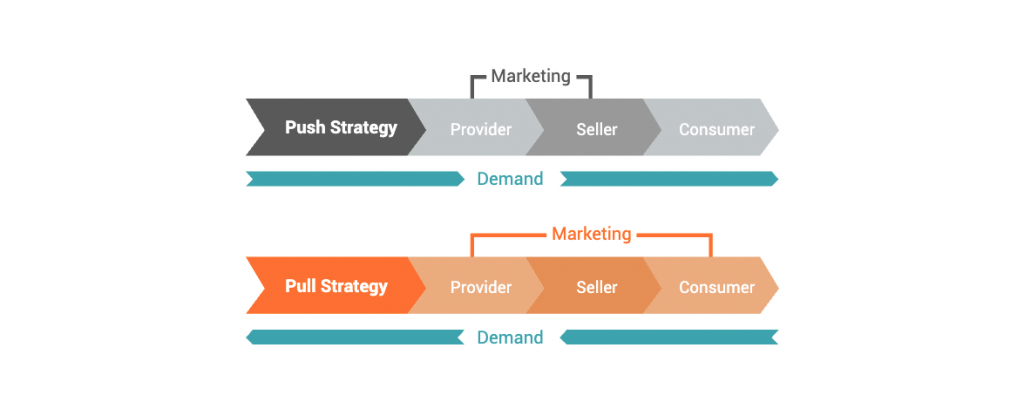

To Push or to Pull: Rethinking Supply Chain Management

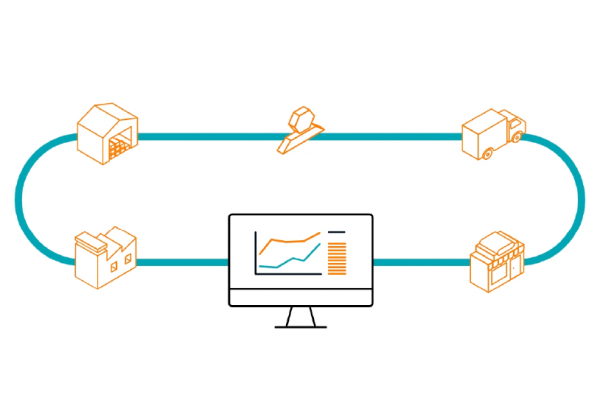

The traditional “push” approach to supply chain management relies on demand forecasting as a starting point to plan procurement, production and fill the distribution channels to support end-customer demand. This approach encourages bulk-ordering practices to exploit economies-of-scale, resulting in long lead-times between orders. Demand forecasting at every stage is based on orders from immediate customers, greatly distorting information regarding true demand. This “bull-whip effect” results in excessive inventory at the wrong stages, routine product stock-outs, expensive expediting and disappointed customers. This approach is still the norm for many companies, but innovative companies are now shifting towards a “pull” based system that measures true demand and responds with a coordinated, responsive supply chain to efficiently meet demand. The ultimate goal of supply chain analytics is to build and supply the right products to targeted customers at the right time and at the right cost. As key information is shared, supply chain analytics solutions can be built to create an efficient network for supply chain management and overall profitability. Advanced analytics can be applied to anticipate demand more accurately, plan supply and replenishment policies, and monitor and react rapidly to abnormalities in the flow of goods and services. Successful organizations take full advantage of their data assets for effective and comprehensive supply chain management.

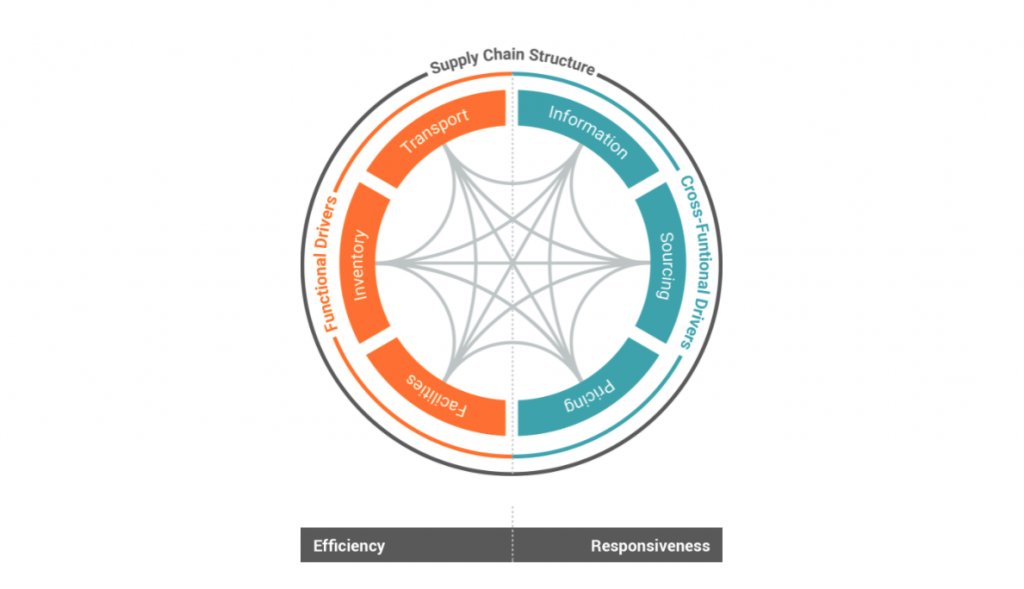

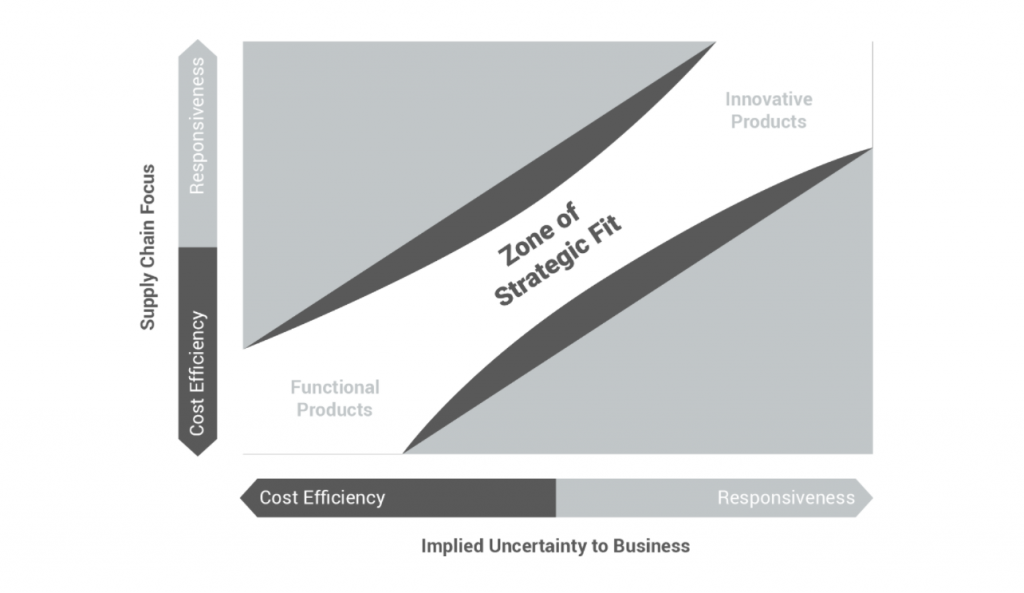

Align Your Supply Chain to your Business Strategy

Companies have greatly increased the focus on supply chain management in recent years. However, this added investment and focus has been largely ineffective due to a lack of structured technological framework to create customized supply chain strategies for different types of products. Functional products such as toothpaste and detergent have relatively stable demand and mostly compete on cost. For these products, supply chain cost efficiency is critical. Innovative products like smart phones and high-end televisions provide better profit margins, but experience significant demand uncertainties. Supply chains for these products have to compete on responsiveness and flexibility. Our analytic solutions help organizations find an effective combination of supply chain strategy and business strategy by designing and controlling the key drivers of supply chain management.

Levers for Supply Chain Management

While supply chains aa great deal in their size and structure, many core drivers for effective supply chain management are consistent across organizations. Analytics platforms and solutions balance these drivers to best align the overall supply chain performance with the objectives of the business.

Facilities: Given the significant capital investment involved, analytics are used to in facility design to ensure they are capable of meeting both short and long term capacity, approach and technology needs. Analytics also help optimize the levels and types of flexibility necessary within individual facilities to thrive under market demand uncertainties. Analytics support facility operations, leading to effective production planning, staffing, scheduling and control strategies.

Inventory: Inventory plays a critical role in supply chains to balance supply and demand. While most companies are still employing outdated and shortsighted local inventory management policies that can greatly contribute to supply chain misinformation and the inefficiencies, leading companies have adopted multi-level inventory optimization techniques to strategically coordinate inventories throughout supply coordinate inventories throughout supply and distribution networks. Warehouse cross-docking, transshipment, and product postponement strategies, combined with product assortment planning analytics, allow companies to manage market pressures for improved financial performance.

Logistics: Fluctuating demand patterns and an expanding base of suppliers and logistics partners have driven companies to continuously rethink their forward and reverse logistics network strategies. Companies can achieve strong ROI improvements through analytics driven planning activities, such as route optimization, load planning, fleet sizing, and freight cost reconciliation. Instead of isolated changes to network metrics, analytics solutions help monitor and adjust network designs periodically for increased cost efficiency.

Sourcing: As businesses expand into new, volatile markets with diversified product portfolios, managing a multitude of suppliers around the world becomes challenging. Signing on each new supplier has considerable costs and potential risks. While competition in the supply chain drives lower prices, the results be counterproductive without proper balancing. Sophisticated analytics programs generate real-time supplier performance management data that supply chain managers can use to improve their sourcing strategy. This data empowers sourcing professionals with analysis and insights from initial screening to ongoing risk management. The result is a holistic, data-driven and efficient supplier selection process.

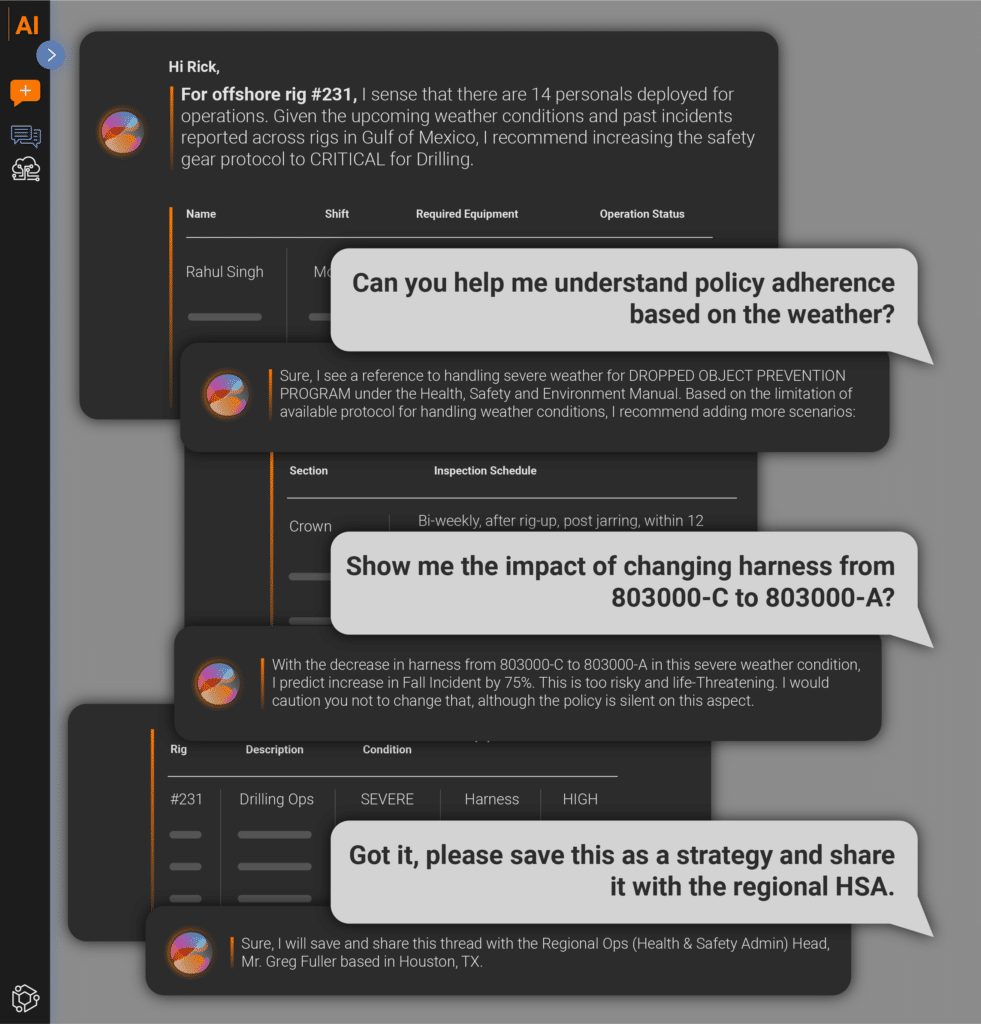

Pricing: Pricing, and more broadly, revenue management, has become a critical driver for many companies in a growing number of industries that suffer from long supply chain lead-times, demand volatility and perishable products. Dynamic pricing strategies enabled by analytic platforms that can mine historical sales transactions and combine them with unstructured data such as weather patterns and chatter on social networks have proved to highly effective in increasing revenues while also improving customer satisfaction.

Information: Information from strategic deployment of information technology is the only driver capable of improving both responsiveness and cost efficiency in the supply chain. This is the key differentiator between supply chains of the past and those of the present. This information is essential to promoting visibility, collaboration, and control throughout the supply chain. This improves and strengthens the supply chain by making data readily available to all stakeholders. Increasing supply chain efficiency begins with enhancing basic metrics and reporting, as they provide essential data for performance improvement initiatives and a full view of the extended supply chain. Advanced analytics that rely on these data streams help organizations make decisions to increase supply chain responsiveness and cost efficiency and minimize customer impact.